Currently in the U.S., there are 34 states which have legalized medicinal cannabis use with an additional six (6) states allowing cannabidiol (CBD) derived from cannabis. Hemp contains little tetrahydrocannabinol (THC) and higher concentrations of CBD. Hemp is federally legal throughout the U.S with manufacturing labs in many states. Globally, there are more than 50 countries which have legalized some variation of medical cannabis use. Many have restrictions on acceptable levels of THC due to its intoxicating properties. The defining factor between state and federally legal markets is that hemp must have ˂ 0.3% THC on a dried weight basis in flower form.

Currently in the U.S., there are 34 states which have legalized medicinal cannabis use with an additional six (6) states allowing cannabidiol (CBD) derived from cannabis. Hemp contains little tetrahydrocannabinol (THC) and higher concentrations of CBD. Hemp is federally legal throughout the U.S with manufacturing labs in many states. Globally, there are more than 50 countries which have legalized some variation of medical cannabis use. Many have restrictions on acceptable levels of THC due to its intoxicating properties. The defining factor between state and federally legal markets is that hemp must have ˂ 0.3% THC on a dried weight basis in flower form.

Cannabis processors are using established scientific techniques to isolate specific cannabinoids from the other 400+ compounds that make up the cannabis plant such as terpenes, lipids, chlorophyll. Many processors rely on techniques which utilize the same equipment used in the distilled liquor industry. Controlled heating and chilling is used throughout the extraction and distillation procedures, and during secondary and tertiary tasks required for further processing.

Increased demand for higher quality and purer products means it’s no longer sufficient to use basic thermometers to monitor and control critical temperatures throughout the processes. Today, precision temperature control and limiting devices are incorporated and considered an essential element for replicating the scientific methodology. Not only do these devices add an extra level of safety to the process, but they allow for improved yields and purer products.

Extraction Processes

Extraction Processes

To properly extract the desired compounds, dried plant material must be milled to a specific size (the size will depend on your equipment). The milled biomass should be free of sticks and stems and consist mainly of flowers and leaves. Once processed, the crude oil will be dark in color, thick in consistency, and contain major and minor cannabinoids as well as other compounds that will be separated and removed through product refinement and purification.

There are several ways to accomplish cannabis extraction and each requires precise temperature control to promote cannabinoid release without degradation. This article will detail the widely used methods that are practiced throughout the globe.

Ethanol Extraction

The simplest method for the home enthusiast as well as large scale producers is ethanol (EtOH) extraction. Ethanol extraction can be accomplished either warm or cold. There are different options for equipment but one specific method for a basic, warm ethanol extraction is outlined below.

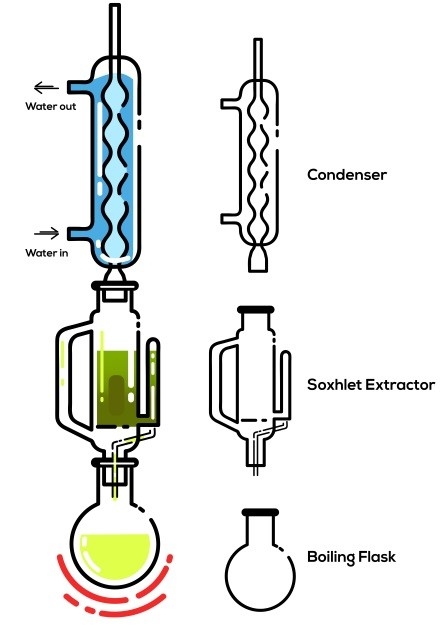

- Food-grade ethanol is placed in a round bottom flask.

- A Soxhlet tube containing plant and filter material is placed above the flask and a condensing tube is placed on top of that.

- As the ethanol is heated, it evaporates and rises to fill the condensing tube.

- Circulating cold water causes the vapor to return to a liquid phase and drop into the Soxhlet tube.

- Cannabinoids (and terpenes) are soluble in ethanol so they’re dissolved and the cannabinoid-rich ethanol drips back into the flask.

- Once the cannabinoid-rich ethanol is collected, other refinement processes might include winterization to remove lipids, filtering, decarboxylation to activate cannabinoids from acidic to neutral forms, and solvent purging to ensure clean products.

Below are some tips to improve system efficiency and increase yield:

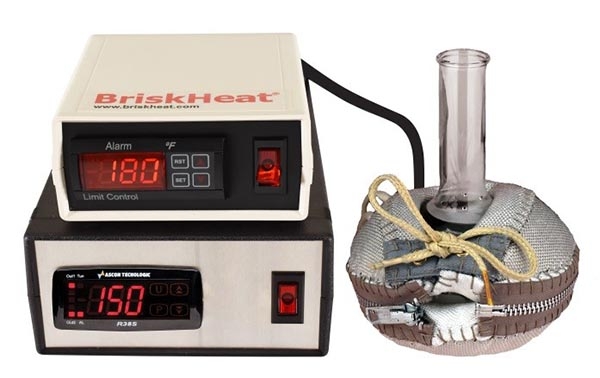

- Metal-housed, soft-sided, or spherical heating mantles are available to uniformly heat more surface area of the flask.

- Flexible heating tapes and custom jacketing can be wrapped around tubing or other pieces of equipment that require heating.

- Use a temperature sensor and PID (proportional-integrative-derivative) temperature controller for each heater.

- Incorporating a high-temperature cut-off controller ensures unexpected high temperatures will not over-pressurize your system causing flammable vapors to escape.

Liquefied Hydrocarbon Extraction

Gases such as butane or propane are pressurized and chilled to liquid form. The liquid is mixed with the plant material to extract cannabinoids and other molecules like terpenes. By slowly heating the solution and reducing the pressure, the liquid changes back into a gas. The solvent is collected and recycled for future use, leaving extract that’s solvent-free. PID temperature controllers can be used for chilling and re-vaporization. Heater manufacturers like BriskHeat Corporation design custom heating mantles to fit tightly around special chamber shapes and sizes.

Supercritical Carbon Dioxide Extraction

Supercritical carbon dioxide (CO2) processing requires heating and pressurization to change CO2 from its gaseous to a liquid state. Above 31.1°C (88°F) and 1,071 PSI, it is known as a supercritical liquid and acts as a solvent. If these parameters drop below those numbers it is considered subcritical. Outlined below is a summarized procedure for supercritical CO2 extraction.

- The supercritical CO2 is passed through a chamber filled with the milled plant material.

- The cannabinoid-rich crude enters a separating chamber where the pressure is lowered.

- At this point, the CO2 returns to a gaseous form and the oil is collected for further processing.

- Degassing using heat is required to remove the remaining solvent.

Temperature control is critical to ensure the product is not overheated. By eliminating degradation from excessive heat, the process results in higher product yield and purer products. Below are some tips to improve system efficiency at this stage:

- A temperature controller using PID control provides for less temperature variation and more control.

- Each heater in the system should have its own temperature sensor and controlling device.

Distillation Processes

Post-extraction, the crude oil contains terpenes and other molecules that may not be desirable in final products. Distillation is a proven method for separating compounds by boiling point including any leftover solvent or terpenes. Any terpenes that are captured in the extraction process (some extraction equipment will separate them but not all) or distillation processes can be saved and added back to final products later for added benefits and aroma. Keep in mind that anything added to your product will lower the purity of your cannabinoids, but terpene additions will augment ensemble effects.

Post-extraction, the crude oil contains terpenes and other molecules that may not be desirable in final products. Distillation is a proven method for separating compounds by boiling point including any leftover solvent or terpenes. Any terpenes that are captured in the extraction process (some extraction equipment will separate them but not all) or distillation processes can be saved and added back to final products later for added benefits and aroma. Keep in mind that anything added to your product will lower the purity of your cannabinoids, but terpene additions will augment ensemble effects.

Further refinement is required to purify and isolate desired cannabinoids. BriskHeat Corporation’s hard-sided mantles cover more surface area on flasks and are available with built-in temperature control. For special shaped chambers, cloth heating mantles with electrical resistance wire heating elements can be used. Hot water-filled jackets may also be used.

Short-Path Distillation

Short-Path distillation is characterized by the extract travelling a short distance for processing.

- A vacuum is applied to reduce the boiling points required for distilling the different compounds.

- Using a hard-sided mantle with a magnetic stirrer, the distillate is heated at different temperatures throughout the process and travels a short distance to the condensing tube to change from vapor to liquid.

- Once condensed, the material is separated into individual bulbs and is now called distillate. Distillate will have a thick consistency and is usually amber in color but it can be golden with multiple passes. Slight heating can reduce the viscosity.

- If CBD isolate is desired, distillate can be further processed to create dry, white, crystallized CBD. This can be added to products to increase the CBD concentration.

Wiped Film Distillation

This distillation method contains several steps and they are summarized below:

This distillation method contains several steps and they are summarized below:

- The crude extract is run through columns where heat is required to reduce the viscosity and evaporate unwanted compounds such as terpenes.

- Crude oil enters the top of a column and mechanical wipers deposit the material on heated walls.

- The process components must be heated, and methods vary, but they consistently include glass or stainless-steel tubing, pumps, small vessels, and dispensing machines.

- Heaters must be extremely flexible in order to contour to a variety of surfaces. In addition, they must be removable, reusable, easily controllable, and moisture and chemical resistant. Silicone heating tapes are great options that adhere to these stipulations.

Conclusion

Heaters, chillers, temperature controllers, and sensors comprise essential equipment used in extracting and refining cannabis oils. Commercially available equipment may have these integrated into the machinery. For those designing and operating their own rigs, it’s important to understand the function of these components and how they can impact the quality and quantity of your product. Using form-fitting flasks, beakers, or cloth mantel heaters, or flexible silicone tapes provide for better heat transfer and more accurate control than older methods using flat hot plates and thermometers.

BriskHeat Corporation specializes in surface and immersion heating solutions including standard and custom mantle heaters, flexible heating tapes, heating blankets, and temperature controllers. Before determining the final selection of equipment for your needs, be sure you consider local building codes, voltage and amperage requirements, and if hazardous area classification is required.