Self-Regulating Heat Tracing Technology

Self-regulating heat trace also known as heating cable, is a straightforward way to maintain temperatures in pipelines, valves, tanks, and other equipment used in varying industries.

In this blog, we're going to look at how self-regulating heating cable works. We’ll then look at what's important when designing your own system and wrap it up with the benefits of choosing heat trace.

How Self-Regulating Heat Trace Works

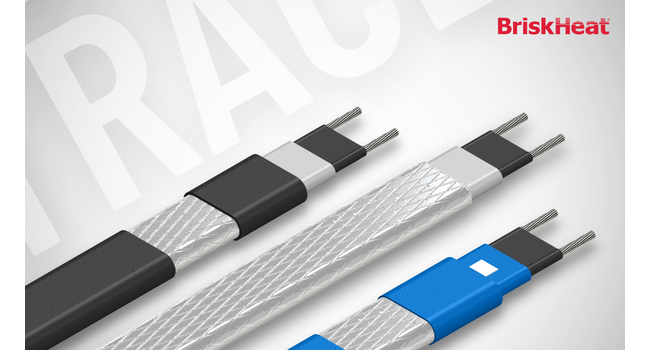

The heating cable itself, is made of two bus wires encased in a semi-conductive core material.

In cold temperatures, the core material between the wires is very conductive, allowing for maximum wattage output. As the temperature of the object being heated increases, the core becomes less conductive. This decreases the wattage in warmer areas while also maintaining higher wattage in colder areas.

What To Look for When Designing Your System

When designing a self-regulating cable system, it is important to know the heating requirements of your system and the dimensions of material to be heated.

For example:

If you need 200 watts to heat a 20-foot-long pipe run. Using 10 watt per foot cable, it need only be laid on the underside of a pipe in a straight run. If 400 watts are required, cable with a smaller watt per foot may be used and spiral-wrapped around the pipe for installation.

Be sure to include accessories needed to complete the installation as well. Ask yourself, will this system require:

Connection Kits: without the proper connection or termination kit, your cut-to-length heating cable won't function properly. If needing a branch connection, use a tee or splice kit.

Fiberglass Tape: feel confident your heating trace is secure with a pressure sensitive adhesive tape.

Insulation: from foam insulators to full coverage cloth, insulators can help reduce additional heat loss.

Temperature Controllers: control a process temperature or automatically cut power to the cable when ambient temperatures rise above the setpoint

Monitor Light Kits: provide your team with a highly visible LED, showing you whether your cable is energized

Planning ahead and preparing for all the important accessories will help make sure your installation will go as smooth as possible.

The Benefits of Self-Regulating Heat Trace

Heat trace technology has several benefits that make it a popular choice for temperature maintenance in various applications.

- Energy Efficiency: heat trace systems are designed to be energy efficient since power consumption is decreased when the ambient or contact temperature increases.

- Safety: The cable uses low voltage and low current, reducing the risk of electrical shock or fire. It is also self-regulating, meaning it cannot over-heat, further reducing the risk of fire or damage to the system. Many materials used to make cable are also flame resistant for use in fire protection systems.

- Reliability: Heat trace systems are reliable and durable. The cable is designed to last for many years and will continue to work after a power supply interruption.

- Easy Installation: Heat trace systems are easy to install, even in complex piping systems. The cable is flexible and can be wrapped around pipe runs when extra heat is required.

- Cost-Effective: Heat trace technology is cost-effective compared to other types of heating systems. The energy efficiency of the cable means lower energy costs, and the low voltage and low current used by the cable reduce the cost of electrical components.

Self-Regulating Heat Trace Applications

Keep in mind, heating cable can be used for a variety of applications. Freeze protection, condensation prevention, viscosity control, and deicing are perfect applications for self-regulating heating cable.

When used alongside a temperature control device, self-regulating cable can also be applied in many more scenarios that require temperatures lower than 250°F (121°C).

Check out a few other heat trace applications below:

Freeze Protection for Natural Gas Production Wells

Heating soil prior to planting or protecting grapevines from freezing

Waste Water Treatment Freeze Protection

Perfume and Flavor Viscosity Control