Cannabinoid Oil Distillation

APPLICATION

Extracting and purifying cannabinoids from cannabis involves a multistep process. The most popular cannabinoids being isolated in the industry right now are tetrahydrocannabinol (THC) and cannabidiol. These are two naturally occurring major cannabinoids, or biologically active chemical compounds found in cannabis. Both are used in various ways to treat medical conditions such as anxiety, sleep problems, movement disorders and chronic pain, and may also be used recreationally depending on state laws.

The process of purifying and isolating cannabinoids starts with extraction, where milled plant material is processed in a way that removes the cannabinoids. There are many methods to achieve this but this step usually involves a solvent such as ethanol or supercritical carbon dioxide. After extraction the cannabis crude oil needs to be further refined to purify and isolate the desired cannabinoids.

A common practice to achieve purification is through distillation. One common distillation process is called “continuous” and is often referred to as “wiped film”. This distillation process contains several steps, and during a couple of these the extract is run through objects where heat is required to reduce the viscosity and evaporate unwanted impurities.

The process components that must be heated vary from method to method, but consistently include glass or stainless-steel tubing, pumps, small vessels, and dispensing machines. Heaters must be extremely flexible in order to contour to a variety of surfaces, removable and reusable, easily controllable between 80 and 100°C (176-212°F), and moisture and chemical resistant. If the heaters do not feature these characteristics, inefficiencies and reduced production can occur, and lead to lost revenue and increased downtime.

SOLUTION

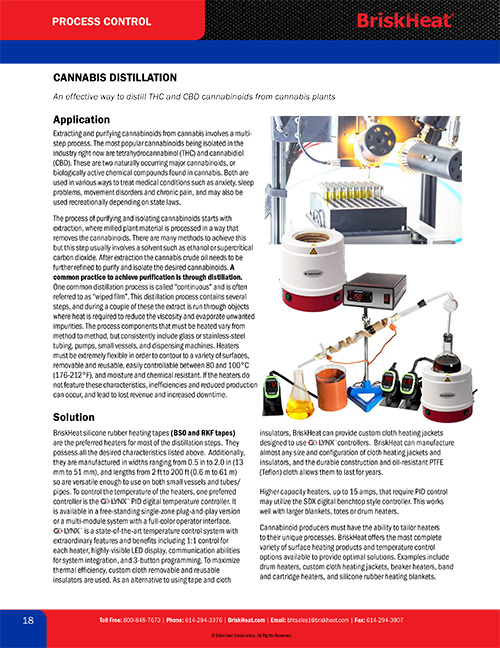

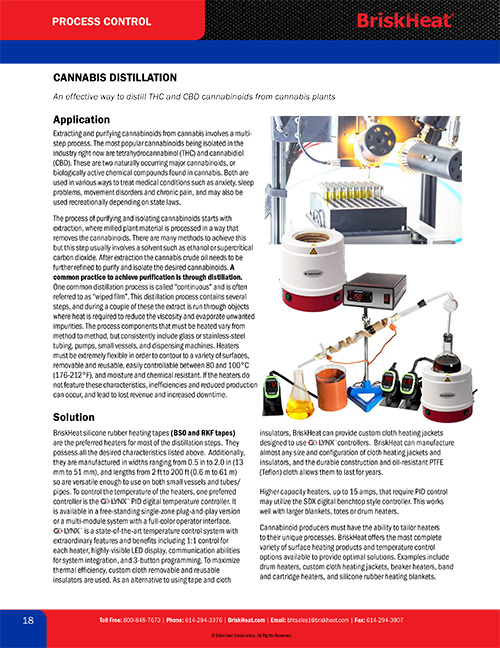

BriskHeat silicone rubber heating tapes (BS0 and RKF tapes) are the preferred heaters for most of the distillation steps. They possess all the desired characteristics listed above. Additionally, they are manufactured in widths ranging from 0.5in (13mm) to 2.0in (51mm), and lengths from 2ft (0.6m) to 200ft (61m) so are versatile enough to use on both small vessels and tubes/pipes.

To control the temperature of the heaters, the preferred controller is the SDX PID digital temperature controller. It features a plug-and-play benchtop design, accuracy of +/- 0.5% of span, programmability in both °F and °C, audible alarm, universal voltage between 100 and 240VAC, 15-amp capacity, and cULus approval for safe use.

To maximize thermal efficiency, custom cloth removable and reusable insulators are used. BriskHeat can manufacture almost any size and configuration insulator, and the durable construction and oil-resistant PTFE (Teflon) cloth allows them to last for years.

Cannabinoid producers must have the ability to tailor heaters to their unique processes. BriskHeat offers the most complete variety of surface heating products and temperature control options available to provide optimal solutions. Examples include , , , , .

Additional Process and Solution:

Another distillation process is called “batch”, which is often called “short path”. This is a smaller, benchtop process that does not have the multiple steps of wiped film. Round-bottom flasks are often used in this process to reduce viscosity and remove impurities. BriskHeat provides a full range of for round-bottom flasks to meet the needs of short path distillation.