Swaged Cartridge Heaters

Description

BriskHeat Swaged Cartridge Heaters are made of high-quality stainless steel and designed for applications where high operating temperatures or heavy vibrations may be present. These durable cartridge heaters are swaged for greater thermal conductivity, making them very efficient.

- High-watt densities for rapid heat-up

- Durability and superior heat transfer acommplished with specially designed cores

- Choose from over 14,00 standard cartridge heater configurations or a custom design

- Temperatures up to 1600°F (871°C)

Part Number

Additional Features:

- Choice of sheath materials for high temperature or corrosive applications

- Distributed wattage puts more power where needed

- Available with integrated thermocouple

- Diameters with custom lengths

- Metric sizes (mm): 6, 6.5, 8, 10, 12, 12.5, 13, 14, 16, 17, 19, 20, 25

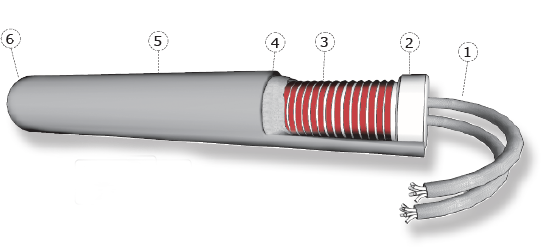

Construction

- TIG-Welded End Disc – To prevent contamination and moisture absorption.

- 304 Stainless-Steel Sheath – For oxidation resistance in a wide variety of environments.

- High-Purity Magnesium Oxide Fill – For maximum dielectric strength and thermal conductivity. Highly compacted for maximum heat transfer.

- Nickel-Chromium Resistance Wire – For maximum heater life, and evenly wound for even heat distribution.

- High-Impact Ceramic Cap – Retards contamination and is suitable for high vibration applications. Deep holes in cap prevent fraying of leads when bent.

- High-Temperature DuraFlex 550 Lead Wires – Max exposure up to 1,022° F (550° C).

Available upon request

Available upon request

For Ordering Charts, See Resources Tab

Custom Options:

Voltage: Up to 480 VAC, Dual 120/240 or 240/480; Single or 3-phase

Power Density: Up to 300 W/in2 (46.5 W/cm2)

Sheath Material: 304 SS, 316 SS, Incoloy

End-Piece Seals: Ceramic, Iava, mica

Lead Termination: Swaged-in, crimped-on, straight pin (posts)

Lead Wire Options: Duraflex, Teflon, Silicone, SJO cord

Potting: Cement, Epoxy, RTV, Epoxy over RTV

Lead Protection: Braid, flexible conduit, convoluted hose, sleeving, right angles, strain relief

Fittings: Brass or SS single NPT, brass or SS double NPT, flange, mechanical stop

Special Construction: Grounded, spring guards, distributive wattage, internal thermocouple, bent

How Long Will My Cartridge Heater Last?

There is no standard heater life in the industry. The life of your heater is affected by:

- Application

- Application Temperature

- Watt Density

- Cycling

- Hole Fit

- Contamination

How Can We Extend the Life of Our Cartridge Heater?

- The number one cause of heater failure is contamination.

- When foreign substances enter the heater and carbonize, this causes arcing and failure inside the heater. If temperature or other circumstances prevent you from using an end seal, avoid substances that could enter the heater at the lead entrance.

- Heat transfer compounds, especially grease based ones, are a common source of contamination.

- Wrapping tape around the lead wires is another common source of contamination as the adhesive melts and runs down into the heater. Remember, any organic or carbon based product has the potential to cause contamination.

- Excessive cycling is the next most common cause of failure. Avoid excessive cycling by properly sizing your heater and not using more wattage than necessary.

- Solid state controllers are also easier on the heaters than simple on-off controllers.

What is the Maximum Temperature for Our Cartridge Heater?

- Maximum exposure temperature is 1022° F (550° C).

Don't see your size or option?

Have a question about which BriskHeat product is right for you?

Need Application assistance? Contact Us. We are here to help!

- Monday - Friday

8:00am - 5:00pm EST

- Worldwide

1-888-412-0122