General Manufacturing

BriskHeat's products are used for a wide variety of applications in manufacturing. Processes that BriskHeat’s products can benefit and make more efficient include: temperature process control, viscosity control, and condensation prevention. BriskHeat’s wide variety of product offerings allows us to customize a solution to specific surface heating application needs. Additionally, there are freeze protection issues which vary by facility, and can benefit from using BriskHeat’s self-regulating heating cable or silicone rubber heating blankets.

Applications

Furniture (Adhesive) Curing

Adhesives used in the furniture assembly process need to be heated and cured to ensure uniformity.

Freeze Protection for Control Panels

Electronic components inside control panels and monitoring devices need protected from cold temperatures. Control panels are often located outdoors and if exposed to sub freezing temperatures, components could fail to operate properly and potentially become permanently damaged.

Freeze Protection for Control Panels

Electronic components inside control panels and monitoring devices need protected from cold temperatures. Control panels are often located outdoors and if exposed to sub freezing temperatures, components could fail to operate properly and potentially become permanently damaged.

Drum, Pail, and Tank Viscosity Control

There are several types of viscous materials like grease, wax, and honey that are stored in drums and pails. These types of materials are thick at room temperature, making flow difficult during pouring, dipping, pumping, coating or mixing operations. Use BriskHeat Drum and Pail Heaters to help reduce the viscosity levels in containers.

Cosmetics Manufacturing

Manufacturing cosmetic creams and lotions involves an emulsion process in which an oil, wax, and/or fat component is combined with a water component and an emulsifying agent. This is often done in a large kettle and heated to elevated temperatures such as 158°F (70°C). The even distribution and precise control of temperature is critical to this application to prevent hardening or burning and is necessa ry for the formula to be consistent from one batch to the next.

Perfume & Flavor Viscosity Control

Grasse, France is considered to be the perfume capital of the world. Heat is required to maximize production and ensure proper dosing of concentrated and (very) expensive oils.

Gas Handling

The temperature of gas within a gas cylinder plays an important role in the efficiency of gas removal. As gas is expelled, the pres sure drops within the cylinder. This pressure drop causes the temperature inside the cylinder to decrease, which makes it increasingly difficult for the gas to vaporize and be expelled.

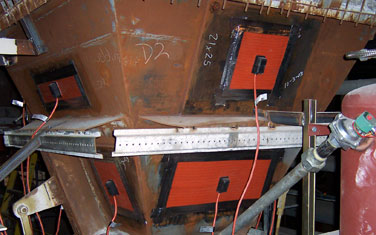

Hopper Heating for General Manufacturing

Manufacturing facilities often use hoppers to collect all different types of materials. These hoppers come in all shapes and sizes and can be found indoors and outdoors.

IBC / TOTE Warming

Users of Intermediate Bulk Containers (IBC) often need to raise the temperature to reduce viscosity or protect the contents from the cold. Maintaining an elevated temperature ensures materials remain ready for production and easy to dispense.

Roof & Gutter Ice Dam Prevention

During cold winter months ice dams form on the edge of rooftops and cause significant roof damage along with safety hazards from falling ice.

Scientific Analytical Instrumentation

In many Research & Development and Laboratory applications, surface heat is required to successfully conduct experiments and tests. The heat may be required for a number of reasons.

Spray Foam Insulation Warming

Spray foam is a popular insulation alternative to traditional building materials such as fiberglass.

Emergency De-icing and Freeze Protection

The cold weather can wreak havoc on exposed valves, pumps, pipes, bearings, filter housing, and other industrial objects. When these parts freeze, they typically become unusable, and in extreme conditions damaged.

Preheating and Welding Steel

When TIG welding thick steel materials, cracking and weld failures can occur due to the extreme thermal stresses imposed by rapid cooling at the weld point. Preheating prior to welding is done to slow the cooling process and reduce the potential for weld failure.