Drum and Pail Viscosity Control

Drum and Pail Viscosity Control

An easy and effective way to improve flow in containers with surface heat

Application

There are several types of viscous materials like grease, wax, and honey that are stored in drums and pails. These types of materials are thick at room temperature, making flow difficult during pouring, dipping, pumping, coating or mixing operations.

Solution

Use BriskHeat Drum and Pail Heaters to help reduce the viscosity levels in containers. They are easy-to-install, use, and provide uniform heat around the container. Uniform, even heat is necessary to prevent sensitive materials from scorching or degrading.

Key Features

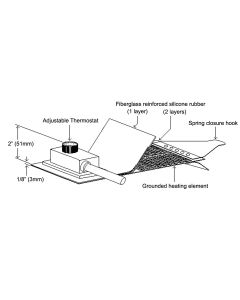

- Choice of silicone rubber band or full-coverage insulated drum heaters.

- Uniform, even heat.

- Plug-and-play.

- Available in 5 to 55-gallon (19 to 208 liter) sizes.

- Heaters designed for metal or plastic drums.

- Temperatures up to 450°F (232°C).

- Patented grounded heating element for safety.

- Hazardous-area rated model available.

- Custom heaters can be made to fit other sizes and application requirements.

Additional Uses

Drum heaters are also used for freeze protection, maintaining materials at elevated temperatures, and melting of solids.

Examples of Materials Stored in Drums

- Agriculture

- Aviation/Aerospace

- Biodiesel

- Concrete/Asphalt

- Catalysts

- Diesel Exhaust Fluid

- Food Processing

- General Manufacturing

- Oil & Gas

- Petrochemical/Chemical

- Processing

- Plastic/Injection Molding

- Pulp & Paper/Packaging

- Surfactants & Chemicals

- Wax & Solid Oils

Shop Drum and Pail Heaters Download printable version