Gas Delivery System Heating

Gas Delivery System Heating

A simple and effective way to prevent condensation

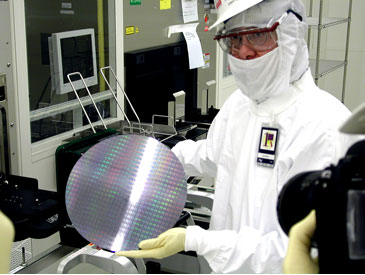

Application

Elevate and/or maintain gas temperatures to ensure process gas is delivered at the proper temperature. Without proper temperature maintenance, condensation will form within gas lines. This condensation will eventually clog the gas line. The result is forced tool shut-downs and down-time due to maintenance. In addition, if processed gas is delivered to the process chamber either too hot or too cold, this can create further issues, leading to a shut-down or extended down-time.

Solution

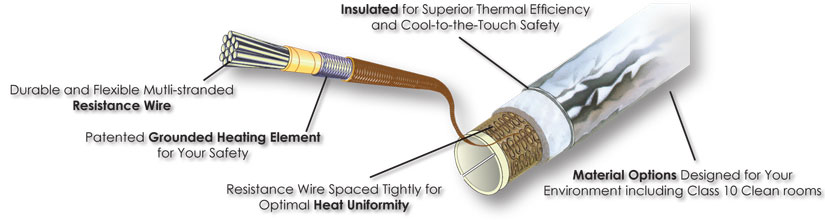

Custom cloth heaters provide the necessary heat for diameters as small as 1/4 inch (6 mm) while the LYNX™ controller maintains the required temperature (and tolerance). The heaters are all connected, and each heater is individually controlled to maximize efficiency and uniformity. All heaters are made to the exact dimensions of the pipes and valves to ensure the consistent heat and long life of the heating system. The LYNX™ System also includes a monitor that shows each heater’s temperature to ensure tolerances are met and downtime is minimized.

Benefits

- Economically reduces condensation build-up and contamination

- Increased productivity

- Decreased maintenance

- Energy-savings

- Safe & cool to the touch (meets SEMI S2 standards)

- Long service life: BriskHeat’s typical heating jacket life is 10+ years. No need for aftermarket parts

Typical Projects

- Gas lines

- Exhaust lines

- Fore lines

- Abatements

- Valves

- Tanks, drums, cylinders, and vessels

- Laboratory equipment

- Analytical equipment

- Vacuum bake-out

- Emission testing

- Fluid delivery systems

- Small and unique geometries