Drum Heater Installation Instructions

Requirements:

- Electrical terminations must be completed by qualified persons

- No special tools or protective equipment is needed to handle this product (specific applications or surfaces may require protective equipment).

- Installation temperature range: -60°F (-51°C) to 131°F (55°C).

- Clearance of 3" (7.5cm) required around vessel during installation.

- Voltage and frequency must be within +/- 10% of the value specified on the product label.

Surface Preparation:

Always install your heater on a clean even surface for optimum performance and longevity. Debris and residue on the surface can not only damage your heater but may also reduce the effectiveness of the heater by reducing the heat transfer between the surface and the heater.

- Remove or avoid contact with sharp edges including rough corners, weld spatter, exposed bolts, etc.

- Remove or avoid contact with rust, stickers, or other coverings.

- Remove oil, moisture, gel and other liquids.

Instructions:

- Inspect heater prior to each installation (see inspection procedure).

- Inspect vessel to be heated for any sharp edges, rust, oil, etc.

- Ensure that there is no combustible material within 12" (30cm) of the surface to be heated.

- Select a suitable location to install the heater. The heater should be located below the lowest expected content level (typically the bottom 1/3) of the vessel.

Do not overlap the heater on itself or another heater. Do not twist the heater or cover any protrusions that may cause an air gap beneath the heater.

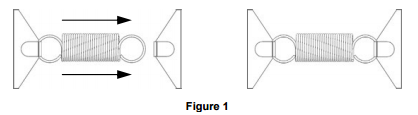

Do not overlap the heater on itself or another heater. Do not twist the heater or cover any protrusions that may cause an air gap beneath the heater. - Wrap the heater around the vessel. Extend the spring attached to the metal tab until it hooks onto the opposing metal tab as shown below.

- Check for any air-gaps between the heater and the vessel.

- Install temperature controlling device if other then adjustable thermostat (See below for DHCX).

Installing the Drum Heater Temperature Sensor (DHCX series)

- Mount the temperature sensor as close as possible to the heater and on the outside of the drum. It is best to mount the sensor vertically. Avoid bending or coiling the capillary tube tighter than a 1/2” (13mm) radius.

Note: The sensing point is the entire length of the sheath 10.5”(267mm). It is important that as much of the bulb’s surface is in contact with the drum as possible.

Do not immerse the sensing bulb into the contents of the drum.

Do not immerse the sensing bulb into the contents of the drum. - Once an appropriate location has been determined, secure the sensor to the drum using aluminum or fiberglass adhesive tape.

CONNECTING HEATER TO POWER SOURCE

Heater equipped with temperature controlling device:

Before connecting the heater to an electrical source, turn the adjustable dial on the heater’s control box in the counter clockwise direction until it stops (this is the off position).

Heaters provided with a plug:

Connect the provided plug to a power supply receptacle.

Heaters provided with wire leads:

The power cable consists of three color-coded conductors: black, white and green. The black wire should be connected to Line 1. The white wire should be connected to Line 2. The green wire should be connected to earth ground. The power connections must be adequately rated to electrically support the voltage and amperage of the heater. The identification label located on the power cord displays voltage and amperage requirements.

OPERATION

DHCH, DHCS, DHLS, DPCH, DPCS, and ECONO series:

This product is equipped with a dial adjustable thermostat temperature controller. A maximum temperature is identified on the label: 425°F (218°C) or 160°F (71°C). Adjust dial to desired heat output . To increase temperature output of the heater, turn the adjustable dial in the clockwise direction. To decrease temperature output of the heater, turn the adjustable dial in the counter clockwise direction. Note: Ambient conditions will affect the dial’s position in which the heater begins to heat. In cooler temperature conditions the heater will begin to heat at a lower temperature position on the dial and in warmer temperature conditions the heater will begin to heat at a higher temperature position on the dial. It is recommended that a thermometer is attached to the vessel being heated. Adjust the dial until you achieve the desired temperature.

Note: Ambient conditions will affect the dial’s position in which the heater begins to heat. In cooler temperature conditions the heater will begin to heat at a lower temperature position on the dial and in warmer temperature conditions the heater will begin to heat at a higher temperature position on the dial.

It is recommended that a thermometer is attached to the vessel being heated. Adjust the dial until you achieve the desired temperature.

Note: Changes in ambient conditions or in the temperature of the contents may cause the temperature to shift over time

For heating temperature sensitive materials that require a specific set-point or have a tight tolerance temperature range Use of an external temperature controlling device is required. Select a temperature controller with the accuracy necessary for the application and is approved for the location and conditions where the drum heater is to be used. For lower temperature applications up to 212°F (100°C) BriskHeat recommends the use of a TC4X Digital Temperature Controller. For higher temperature applications BriskHeat recommends the use of a TTD Digital Temperature Controller.

Note: If assistance determining a proper temperature controlling device is required for your application, please contact BriskHeat or your local distributor for application assistance and product solutions.

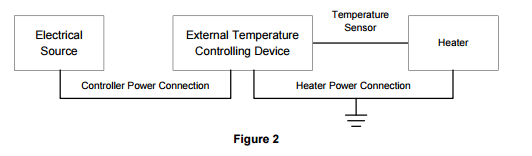

Install and connect the external temperature controlling device between the drum heater and the electrical source as shown in Figure 2. Install the temperature controlling device in accordance with manufacturer’s installation instructions.

Ensure a grounded connection is provided and if the temperature controlling device does not support a grounded connection, ensure an approved earth ground source is provided.

Mount the temperature sensor between the heater’s metal tab and the outside of the container. Secure the sensor to the container using appropriately rated aluminum or fiberglass adhesive tape.

Set the drum heater’s temperature controlling dial to the maximum temperature setting. Adjust heater output using the external temperature controlling device.

MAINTENANCE INSTRUCTIONS

Maintenance:

- All maintenance should be performed after heater has cooled to room temperature and with the electricity disconnected.

- This product should be inspected prior to being installed and at least every 3 months during use.

- Dirt, oil, grease or other foreign matter can be removed with a damp rag and mild household cleaners.

- Do not attempt to repair a damaged heater.

- Inspection should be performed after the heater has cooled to room temperature and with the electricity disconnected.

- The heater should be free of any cuts, cracks, or punctures.

- The power leads should not have any visible breaks in their insulation

- The heater should be free of any build-up of dirt, oil, grease, or other foreign matter.

- This product should be stored indoors.

Disposal:

- This product does not contain any hazardous substances and may be discarded with domestic waste.

For PDF version of the complete manual instructions, please click here

Shop all Drum Heaters: